正在建设中,敬请期待

نصائح دافئة

Tips

Tips

Please improve your information and become a senior member

نصائح دافئة

Tips

Trusted stores

Trusted stores

Direct sales

Direct sales

Instant prices

Instant prices

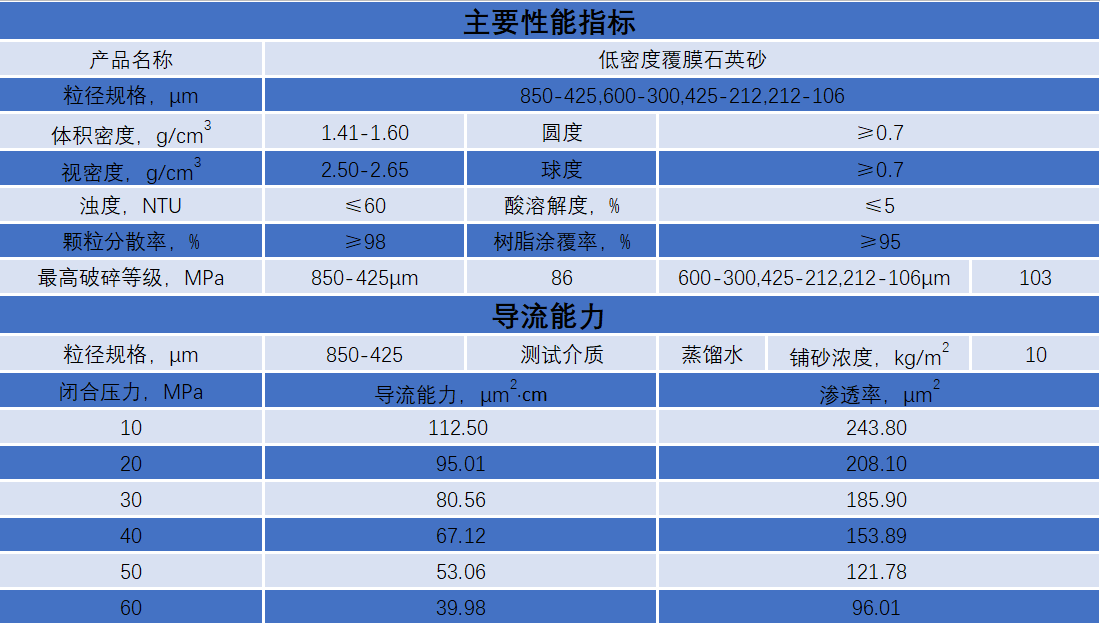

product

Low-density coated sand

product

Low-density coated sand  You may also like

You may also like

Low-density coated sand is processed using our company's unique ball milling scrubbing technology, chemical coating technology, and multi-layer coating technology.

"Ball milling scrubbing technology" refers to the process where quartz sand aggregates with more than 95% silicon dioxide content are selected by our company and subjected to ball milling, water washing, and acid washing processes to achieve higher roundness, sphericity, and strength. The nearly spherical silicon dioxide aggregates provide a fundamental guarantee for excellent flow conductivity.

"Chemical coating technology" refers to the process where polymer membrane materials form an integrated single particle with quartz sand aggregates through high-temperature melting. This is different from traditional coating technologies, and the new type of proppants processed with chemical coating technology have further improved compressive strength.

"Multi-layer coating technology" refers to the selection of polymer materials and modified materials with different performance characteristics such as thermoplastic and thermosetting properties during the coating process. Coating is carried out in batches to form a multi-structure membrane. Compared with traditional single-structure membranes, multi-structure membrane proppants have better roundness, sphericity, strength, and acid and alkali resistance. They effectively ensure 100% particle coating and 100% surface coating of particles, while effectively repairing the sphericity of quartz sand aggregates, significantly improving long-term flow capacity.

No Data Available

No Data Available

share

share

service

service

top

top

Tips

商家中心

商家中心

全部展商分类

全部展商分类

勘探与生产

勘探与生产

工程技术服务

工程技术服务

石油工程建设

石油工程建设

石油装备制造

石油装备制造

天然气与管道

天然气与管道

油田数字化

油田数字化

低碳新能源

低碳新能源

石油化工产品

石油化工产品

物流运输

物流运输

设备五金

设备五金

wechat sharing

wechat sharing

link sharing

link sharing

链接全球

链接全球  精准匹配

精准匹配  在线互动

在线互动  品牌提升

品牌提升  多方共赢

多方共赢  扫码关注公众号

扫码关注公众号  扫码进入移动端

扫码进入移动端