正在建设中,敬请期待

نصائح دافئة

Tips

Tips

Please improve your information and become a senior member

نصائح دافئة

Tips

Trusted stores

Trusted stores

Direct sales

Direct sales

Instant prices

Instant prices

product

Heating Cable

product

Heating Cable  You may also like

You may also like

No Data Available

No Data Available

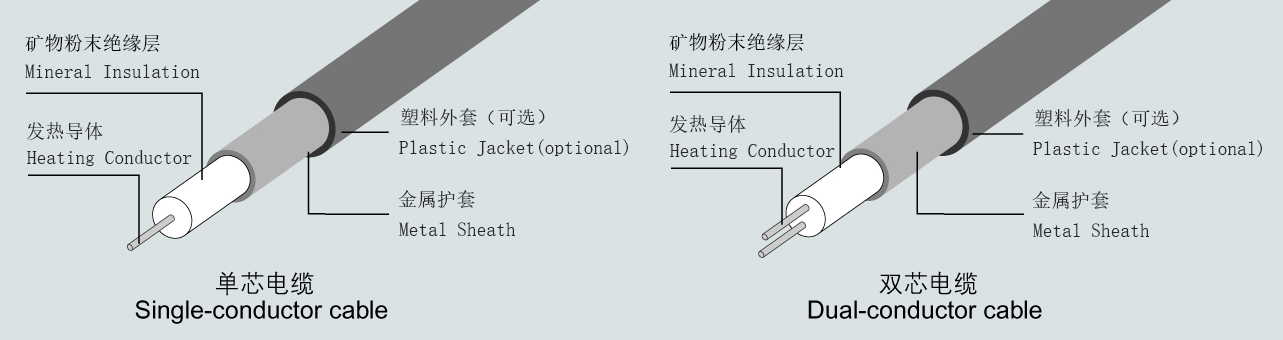

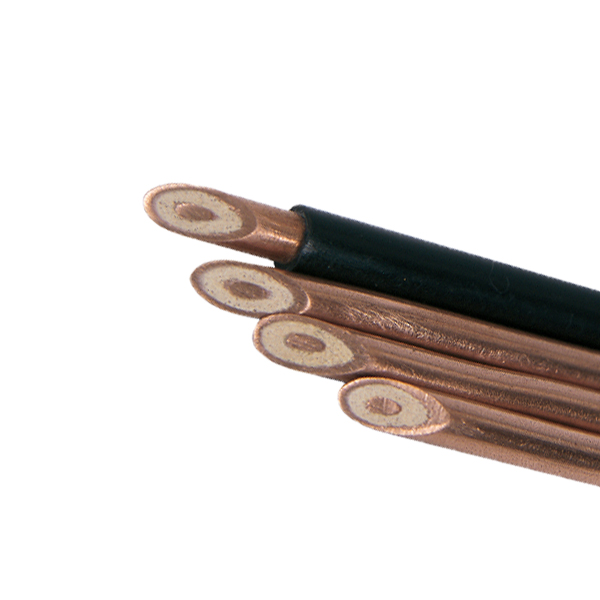

Product structure

Mineral Insulated Heating Cable

It is composed of a heating conductor, an insulating layer of tightly compacted mineral powder (usually magnesium oxide powder) and a metal sheath. For copper sheathed heating cables, a layer of high-density polyethylene (HDPE) or flame-retardant HDPE plastic jacket can be extruded on the outer circumference of the metal sheath according to the needs of anti-corrosion and anti-mechanical damage in the place of use.

The common structure is single-core and two-core, and three-core and above mineral insulated heating cables can also be designed and provided according to your needs.

Sheath materials include copper, cupronickel, austenitic stainless steel (304L, 321, 316L, 347, etc.), inconel and 825 high temperature corrosion resistant alloy, etc., which should be carried out according to different operating temperatures and corrosive environments Optional.

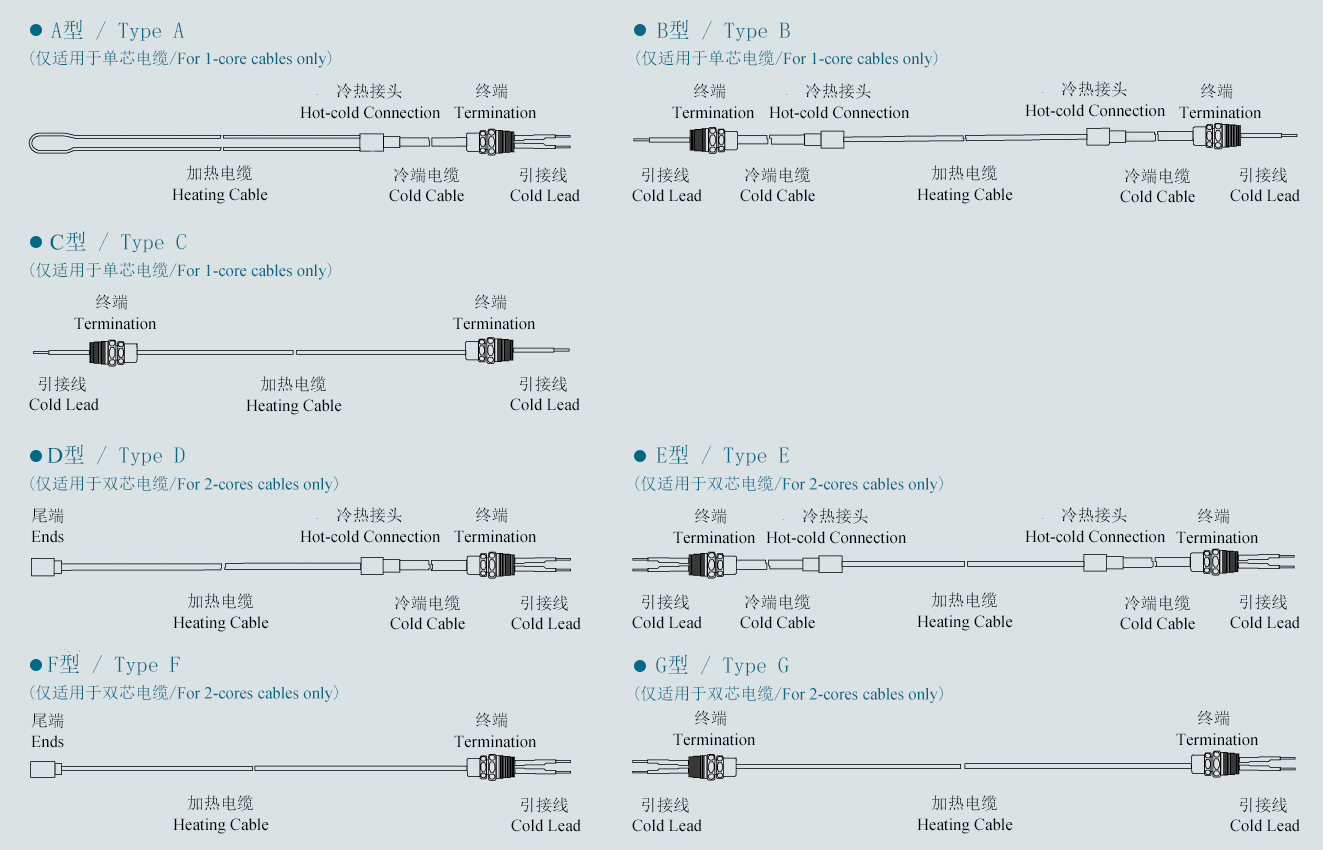

Mineral Insulated Heating Unit (Mineral Insulated Heating Unit)

This product is based on the design and selection of mineral insulated heating cables, and is prefabricated in the manufacturer's factory for heating unit devices that can be directly connected to the power supply. It is usually composed of heating cables, hot and cold joints, cold end cables, terminals, tail ends, and lead wires. There are types A, B, C, D, E, F, and G. Types A, B, and C are only suitable for single-core heating cables, and types D, E, F, and G are only suitable for double-core heating cables.

Product characteristics

High mechanical strength

The high-strength metal tube is used as the sheath, which forms a compact body with the conductor and mineral insulating powder during the processing. The structure is firm, the mechanical strength is high, and it is resistant to mechanical extrusion and bending.

Stable physical and chemical properties

The constituent materials are all inorganic materials with good thermal stability. When used under the rated temperature and set environment, the structure, electrical conductivity, dielectric strength, chemical composition and other mechanical, physical and chemical properties are quite stable.

Small temperature difference between inside and outside

The thermal resistance coefficient of magnesium oxide insulation is 3-5 times lower than that of most organic insulating materials. The small thermal resistance can make the heat transfer from the inner conductor to the metal sheath sharply, so the temperature difference between the conductor and the surface of the sheath is very small, which allows a larger current density.

High electric and heat conversion efficiency

Using the principle of the thermal effect of electric current (Joule-Lenz's law), pure resistance heats up, almost 100% of the electrical energy is converted into heat.

Electrical control is convenient

The working voltage is 50-60HZ power frequency, and the ON/OFF or PID temperature control is selected according to actual needs. The technology is mature, the operation is reliable, and the maintenance is small.

Corrosion resistance

According to the temperature of the environment and the corrosive medium, the appropriate metal sheath material can be selected to achieve the best corrosion resistance.

Radiation resistance

The inorganic materials used have good radiation resistance. The literature shows that when this type of cable runs at 200℃-700℃ and the neutron flux is 1021 neutrons/cm2, its technical performance actually does not occur. Changes can be applied to the core radiation area of nuclear power plants.

Explosion-proof certificate

The company's mineral insulated heating cable products have obtained the IEC Ex and ATEX explosion-proof certificates issued by the British CML.

Application Area

Chemical industry

The heating or tracing of process pipelines and accessories, pumps;

The heating or tracing of reactors, cracking furnaces, vaporizers, flash evaporators, storage tanks, storage tanks and other devices and containers.

Petroleum field

Heating or tracing of Christmas trees, crude oil technology pipelines, valves, oil pumps, storage tanks and related processing devices;

Heavy oil wellbore heats up to reduce viscosity;

Oil and gas well wax prevention and deblocking.

Metallurgical industry

Heating or tracing of chemical pipelines, storage tanks, etc.;

The coal-fired dust collecting ash hopper is heated.

Power Station

Oil-fired power station: oil pipeline, container oil supply heating and heat tracing;

Hydropower station: pipeline antifreeze heating and heat tracing;

Nuclear power plants: heating or tracing of pipelines, valves, pumps, storage tanks, etc. of various systems, and preheating of the reactor sodium loop;

CSP stations: heating and tracing of lava pipelines and accessories, lava pumps, collectors, storage tanks, etc.

Natural gas

Gas station vaporization heat compensation;

Air tank water sealing heating;

Catalytic reaction heating;

The heating or tracing of natural gas product pipelines and related accessories and devices.

Architecture field

Quick drying of cement, pre-drying and heating of refractory bricks;

Floor heating for residential and industrial buildings;

Roof melting ice and snow drop load;

Gutter and downpipe anti-icing and heating.

Ship field

Deck and cabin anti-condensation heating;

Water and steam pipelines and related devices are heated or traced.

Horticulture field

Winter heating of greenhouse crops;

Prevent ice and snow in the greenhouse;

Promote seed growth and heating;

Lawn maintenance and heat preservation.

Roads, traffic fields

Roads, ramps, sidewalks, steps, bridges and tunnels are heated by melting ice and snow;

Snow and ice melting in sports fields, airport runways, and helipads;

Anti-freezing of railway turnouts, melting of icicles on the dome of tunnels, and melting of snow and ice on open-air platforms.

300VCopper sheathed heating cable (model:MICU)

Specification code | Outer diameter | Nominal resistance of conductor at 20℃ | Maximum manufacturing length | Unit weight |

mm | Ω/km | m | Kg/km | |

23C3.4 | 12.4 | 3.4 | 200 | 698 |

23C4.4 | 11.3 | 4.4 | 220 | 571 |

23C5.8 | 10.4 | 5.8 | 240 | 476 |

23C8.6 | 9.0 | 8.6 | 260 | 351 |

23C11.4 | 8.4 | 11.4 | 280 | 299 |

23C13.8 | 8.0 | 13.8 | 300 | 268 |

23C17.2 | 7.6 | 17.2 | 320 | 239 |

23C23 | 7.1 | 23 | 340 | 205 |

23C34.4 | 6.6 | 34.4 | 360 | 174 |

23C49.2 | 6.2 | 49.2 | 380 | 151 |

23K160 | 10.4 | 160 | 220 | 477 |

23K240 | 9.0 | 240 | 240 | 351 |

23K320 | 8.4 | 320 | 265 | 299 |

23K384 | 8.0 | 384 | 280 | 268 |

23K480 | 7.7 | 480 | 300 | 244 |

23K640 | 7.1 | 640 | 320 | 205 |

23K960 | 6.5 | 960 | 350 | 169 |

Note: The nominal resistance of the double-core cable conductor is the resistance of the double-core loop per 1km, that is, twice the resistance of a single conductor. | ||||

300VWhite copper sheathed heating cable (model:MICN)

Specification code | Outer diameter | Nominal resistance of conductor at 20℃ | Maximum manufacturing length | Unit weight |

mm | Ω/km | m | Kg/km | |

23K160 | 10.4 | 160 | 202 | 477 |

23K240 | 9.0 | 240 | 267 | 351 |

23K300 | 8.4 | 300 | 292 | 302 |

23K380 | 8.0 | 380 | 320 | 269 |

23K480 | 7.7 | 480 | 352 | 244 |

23K620 | 7.1 | 620 | 433 | 206 |

23K960 | 6.5 | 960 | 458 | 169 |

23K1480 | 6.0 | 1480 | 390 | 141 |

23K1890 | 5.7 | 1890 | 433 | 126 |

23K2340 | 5.5 | 2340 | 471 | 117 |

23K3100 | 5.3 | 3100 | 500 | 107 |

23K4800 | 4.9 | 4800 | 547 | 92 |

Note: The nominal resistance of the double-core cable conductor is the resistance of the double-core loop per 1km, that is, twice the resistance of a single conductor. | ||||

300VStainless steel/825Alloy sheathed heating cable (model:MISS/MIAL)

Specification code | Outer diameter | Nominal resistance of conductor at 20℃ | Maximum manufacturing length | Unit weight |

mm | Ω/km | m | Kg/km | |

23C34 | 5.6 | 34 | 190 | 122 |

23K164 | 5.0 | 164 | 240 | 95 |

23K180 | 6.5 | 180 | 140 | 169 |

23K210 | 5.4 | 210 | 210 | 113 |

23K230 | 4.8 | 230 | 261 | 86 |

23K300 | 5.0 | 300 | 240 | 96 |

23K328 | 4.5 | 328 | 297 | 78 |

23K400 | 4.8 | 400 | 261 | 87 |

23K480 | 4.8 | 480 | 261 | 86 |

23K650 | 4.6 | 650 | 284 | 78 |

23K984 | 4.8 | 984 | 261 | 86 |

23K1000 | 4.1 | 1000 | 358 | 61 |

23K1300 | 3.8 | 1300 | 417 | 52 |

23K1600 | 4.3 | 1600 | 325 | 68 |

23K1968 | 4.8 | 1968 | 261 | 87 |

23K2000 | 5.0 | 2000 | 241 | 93 |

23K2297 | 4.5 | 2297 | 297 | 76 |

23K2400 | 4.8 | 2400 | 261 | 86 |

23K3000 | 4.6 | 3000 | 284 | 78 |

23K4593 | 4.0 | 4593 | 375 | 58 |

23N4600 | 4.8 | 4600 | 261 | 86 |

23N5577 | 4.0 | 5577 | 375 | 60 |

23N7500 | 4.6 | 7500 | 284 | 77 |

23N8200 | 4.0 | 8200 | 375 | 59 |

23N11200 | 4.4 | 11200 | 311 | 70 |

23N14000 | 4.2 | 14000 | 341 | 63 |

23N16400 | 3.5 | 16400 | 495 | 44 |

23N18000 | 3.8 | 18000 | 420 | 52 |

23N19685 | 3.5 | 19685 | 495 | 44 |

23N24600 | 3.0 | 24600 | 670 | 33 |

23N26000 | 3.6 | 26000 | 464 | 46 |

23N29500 | 3.0 | 29500 | 670 | 32 |

23N36000 | 3.4 | 36000 | 520 | 41 |

23N40000 | 3.4 | 40000 | 520 | 41 |

23N50000 | 3.6 | 50000 | 464 | 41 |

23N60000 | 3.6 | 60000 | 464 | 41 |

23N72000 | 3.4 | 72000 | 520 | 40 |

Note: The nominal resistance of the double-core cable conductor is the resistance of the double-core loop per 1km, that is, twice the resistance of a single conductor. | ||||

600VCopper sheathed heating cable (model:MICU)

Specification code | Outer diameter | Nominal resistance of conductor at 20℃ | Maximum manufacturing length | Unit weight |

mm | Ω/km | m | Kg/km | |

16C0.7 | 9.6 | 0.7 | 340 | 497 |

16C0.9 | 9.1 | 0.9 | 340 | 427 |

16C1.0 | 8.7 | 1.0 | 350 | 390 |

16C1.3 | 8.0 | 1.3 | 350 | 321 |

16C1.7 | 7.3 | 1.7 | 350 | 261 |

16C2.2 | 7.0 | 2.2 | 380 | 232 |

16C2.9 | 6.4 | 2.9 | 400 | 190 |

16C4 | 5.9 | 4 | 600 | 156 |

16C7 | 5.3 | 7 | 600 | 119 |

16C11 | 4.9 | 11 | 600 | 99 |

16C13 | 4.6 | 13 | 600 | 87 |

16C17 | 4.6 | 17 | 600 | 85 |

16C21 | 4.6 | 21 | 600 | 84 |

16C25 | 3.7 | 25 | 600 | 55 |

16C33 | 4.6 | 33 | 600 | 82 |

16C40 | 3.4 | 40 | 600 | 45 |

16C63 | 3.2 | 63 | 600 | 39 |

16K66 | 5.2 | 66 | 384 | 114 |

16K80 | 5.3 | 80 | 370 | 120 |

16K100 | 5.2 | 100 | 450 | 112 |

16K131 | 4.9 | 131 | 600 | 99 |

16K140 | 4.9 | 140 | 600 | 98 |

16K197 | 4.45 | 197 | 600 | 79 |

16K220 | 4.5 | 220 | 600 | 81 |

16K262 | 4.3 | 262 | 600 | 73 |

16K315 | 4.3 | 315 | 600 | 78 |

16K345 | 4.2 | 345 | 600 | 74 |

16K450 | 4.0 | 450 | 600 | 66 |

16K492 | 4.0 | 492 | 600 | 65 |

16K630 | 4.0 | 630 | 600 | 64 |

16K800 | 3.5 | 800 | 600 | 49 |

16K984 | 4.0 | 984 | 600 | 62 |

16K1280 | 3.7 | 1280 | 600 | 53 |

16K2000 | 3.6 | 2000 | 600 | 49 |

16K3000 | 3.6 | 3000 | 600 | 49 |

26C3.4 | 12.9 | 3.4 | 150 | 745 |

26C4.4 | 12.2 | 4.4 | 160 | 650 |

26C5.8 | 11.3 | 5.8 | 170 | 547 |

26C8.6 | 9.9 | 8.6 | 180 | 413 |

26C11.4 | 9.3 | 11.4 | 200 | 357 |

26C13.8 | 9.0 | 13.8 | 210 | 332 |

26C17.2 | 8.6 | 17.2 | 220 | 299 |

26C23 | 8.0 | 23 | 250 | 255 |

26C34.4 | 7.5 | 34.4 | 280 | 220 |

26C49.2 | 7.1 | 49.2 | 300 | 195 |

26K240 | 9.9 | 240 | 180 | 413 |

26K320 | 9.3 | 320 | 200 | 357 |

26K384 | 9.0 | 384 | 210 | 332 |

26K480 | 8.6 | 480 | 220 | 299 |

26K640 | 8.0 | 640 | 250 | 255 |

26K960 | 7.5 | 960 | 280 | 220 |

Note: The nominal resistance of the double-core cable conductor is the resistance of the double-core loop per 1km, that is, twice the resistance of a single conductor. | ||||

600VWhite copper sheathed heating cable (model:MICN)

Specification code | Outer diameter | Nominal resistance of conductor at 20℃ | Maximum manufacturing length | Unit weight |

mm | Ω/km | m | Kg/km | |

16C3 | 6.4 | 3 | 255 | 188 |

16C4 | 5.9 | 4 | 300 | 156 |

16C5 | 5.7 | 5 | 320 | 142 |

16C6 | 5.5 | 6 | 345 | 130 |

16C7 | 5.3 | 7 | 350 | 119 |

16C8 | 5.2 | 8 | 362 | 113 |

16C9 | 5.1 | 9 | 376 | 108 |

16C11 | 4.9 | 11 | 400 | 99 |

16C17 | 4.6 | 17 | 500 | 85 |

16C25 | 3.7 | 25 | 600 | 55 |

16C40 | 3.4 | 40 | 600 | 45 |

16C63 | 3.2 | 63 | 300 | 39 |

16K82 | 5.7 | 82 | 350 | 165 |

16C93 | 3.2 | 93 | 300 | 39 |

16K122 | 5.2 | 122 | 400 | 125 |

16K160 | 4.9 | 160 | 500 | 108 |

16K188 | 4.7 | 188 | 600 | 98 |

16K250 | 4.4 | 250 | 600 | 84 |

16K312 | 4.2 | 312 | 600 | 75 |

16K400 | 4.0 | 400 | 600 | 67 |

16K478 | 3.8 | 478 | 600 | 60 |

16K630 | 3.7 | 630 | 600 | 55 |

16K1000 | 3.4 | 1000 | 600 | 46 |

16K1600 | 3.2 | 1600 | 600 | 40 |

16K2210 | 3.2 | 2210 | 300 | 39 |

16K2400 | 3.1 | 2400 | 600 | 37 |

16K4150 | 3.0 | 4150 | 600 | 34 |

26K160 | 11.2 | 160 | 184 | 539 |

26K240 | 9.9 | 240 | 226 | 413 |

26K300 | 9.3 | 300 | 246 | 360 |

26K380 | 9.0 | 380 | 273 | 332 |

26K480 | 8.6 | 480 | 292 | 299 |

26K620 | 8.0 | 620 | 327 | 256 |

26K960 | 7.5 | 960 | 352 | 220 |

26K1480 | 7.1 | 1480 | 305 | 194 |

26K1600 | 6.0 | 1600 | 405 | 141 |

26K1890 | 6.8 | 1890 | 335 | 178 |

26K2340 | 6.4 | 2340 | 361 | 157 |

26K3100 | 6.2 | 3100 | 380 | 146 |

26K4800 | 5.8 | 4800 | 422 | 127 |

Note: The nominal resistance of the double-core cable conductor is the resistance of the double-core loop per 1km, that is, twice the resistance of a single conductor. | ||||

600Stainless steel/825Alloy copper sheathed heating cable (model:MISS/MIAL )

Specification code | Outer diameter | Nominal resistance of conductor at 20℃ | Maximum manufacturing length | Unit weight |

mm | Ω/km | m | Kg/km | |

16C2.1 | 6.8 | 2.1 | 130 | 214 |

16C2.8 | 6.0 | 2.8 | 165 | 165 |

16C3.4 | 5.9 | 3.4 | 170 | 153 |

16C3.6 | 6.1 | 3.6 | 160 | 160 |

16C5.3 | 5.3 | 5.3 | 210 | 118 |

16C8 | 4.7 | 8 | 150 | 91 |

16C8.5 | 4.7 | 8.5 | 150 | 90 |

16C13 | 4.3 | 13 | 190 | 73 |

16C21 | 4.0 | 21 | 220 | 61 |

16K40 | 5.8 | 40 | 180 | 149 |

16K50 | 5.4 | 50 | 210 | 127 |

16K60 | 5.2 | 60 | 220 | 115 |

16K80 | 4.8 | 80 | 200 | 96 |

16K100 | 4.7 | 100 | 160 | 90 |

16K120 | 4.5 | 120 | 170 | 81 |

16K131 | 4.0 | 131 | 215 | 63 |

16K153 | 4.2 | 153 | 195 | 70 |

16N160 | 6.5 | 160 | 150 | 188 |

16N200 | 5.9 | 200 | 180 | 154 |

16N250 | 5.3 | 250 | 220 | 124 |

16K328 | 4.0 | 328 | 215 | 60 |

16N400 | 4.7 | 400 | 280 | 93 |

16N500 | 4.5 | 500 | 300 | 84 |

16N630 | 4.3 | 630 | 200 | 75 |

16N900 | 3.9 | 900 | 230 | 60 |

16N1000 | 3.9 | 1000 | 230 | 59 |

16N1250 | 3.8 | 1250 | 210 | 55 |

16N1600 | 3.6 | 1600 | 270 | 49 |

16N2400 | 3.2 | 2400 | 350 | 38 |

16N2500 | 3.4 | 2500 | 300 | 43 |

16N2800 | 3.4 | 2800 | 300 | 42 |

16N3300 | 3.4 | 3300 | 300 | 42 |

16N4000 | 3.2 | 4000 | 350 | 37 |

16N5200 | 3.2 | 5200 | 350 | 37 |

16N6300 | 3.2 | 6300 | 350 | 36 |

16N10000 | 3.2 | 10000 | 350 | 36 |

16N20000 | 3.2 | 20000 | 350 | 36 |

26C8.4 | 9.8 | 8.4 | 60 | 386 |

26C13.4 | 8.7 | 13.4 | 80 | 296 |

26C21 | 7.9 | 21 | 95 | 238 |

26C34 | 7.3 | 34 | 110 | 198 |

26C54 | 6.3 | 54 | 150 | 146 |

26C85 | 5.6 | 85 | 190 | 114 |

26C130 | 5.3 | 130 | 215 | 101 |

26K180 | 7.9 | 180 | 95 | 245 |

26K260 | 7.4 | 260 | 110 | 210 |

26K360 | 6.8 | 360 | 130 | 175 |

26K500 | 6.4 | 500 | 147 | 153 |

26K650 | 5.9 | 650 | 173 | 129 |

26K1000 | 5.7 | 1000 | 185 | 118 |

26K1300 | 6.2 | 1300 | 156 | 143 |

26K2000 | 5.8 | 2000 | 179 | 123 |

26K3300 | 5.4 | 3300 | 206 | 105 |

26N4600 | 5.8 | 4600 | 179 | 123 |

26N8000 | 5.4 | 8000 | 206 | 105 |

26N13000 | 5.0 | 13000 | 241 | 89 |

26N27000 | 4.8 | 27000 | 261 | 81 |

26N40000 | 4.6 | 40000 | 284 | 74 |

26N60000 | 4.4 | 60000 | 311 | 68 |

26N72000 | 4.2 | 72000 | 341 | 62 |

Note: The nominal resistance of the double-core cable conductor is the resistance of the double-core loop per 1km, that is, twice the resistance of a single conductor. | ||||

Mineral insulated cold end cable specification table

Voltage level | Specifications | Number of conductor cores | Nominal cross section (mm2) | Nominal outer diameter (mm) | Conductor resistance at 20℃ Maximum (Ω/km) | Current carrying capacity (A) |

500V | 2L1.5 | 2 | 1.5 | 5.7 | 12.1 | 20 |

750V | 1H1.5 | 1 | 1.5 | 4.9 | 12.1 | 25 |

1H2.5 | 1 | 2.5 | 5.3 | 7.41 | 34 | |

1H4 | 1 | 4 | 5.9 | 4.61 | 46 | |

1H6 | 1 | 6 | 6.4 | 3.08 | 57 | |

1H10 | 1 | 10 | 7.3 | 1.83 | 77 | |

1H16 | 1 | 16 | 8.3 | 1.15 | 108 | |

2H1.5 | 2 | 1.5 | 7.9 | 12.1 | 25 | |

2H2.5 | 2 | 2.5 | 8.7 | 7.41 | 34 | |

2H4 | 2 | 4 | 9.8 | 4.61 | 46 |

No Data Available

No Data Available

share

share

service

service

top

top

Tips

商家中心

商家中心

全部展商分类

全部展商分类

勘探与生产

勘探与生产

工程技术服务

工程技术服务

石油工程建设

石油工程建设

石油装备制造

石油装备制造

天然气与管道

天然气与管道

油田数字化

油田数字化

低碳新能源

低碳新能源

石油化工产品

石油化工产品

物流运输

物流运输

设备五金

设备五金

wechat sharing

wechat sharing

link sharing

link sharing

链接全球

链接全球  精准匹配

精准匹配  在线互动

在线互动  品牌提升

品牌提升  多方共赢

多方共赢  扫码关注公众号

扫码关注公众号  扫码进入移动端

扫码进入移动端