正在建设中,敬请期待

نصائح دافئة

Tips

Tips

Please improve your information and become a senior member

نصائح دافئة

Tips

Trusted stores

Trusted stores

Direct sales

Direct sales

Instant prices

Instant prices

product

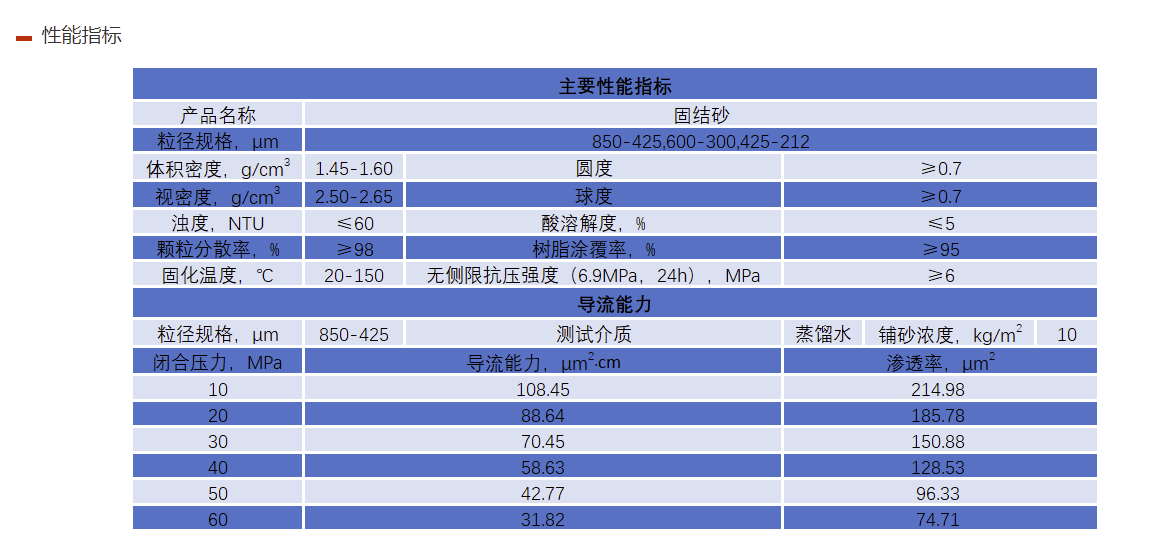

Consolidated Sand

product

Consolidated Sand  You may also like

You may also like

Based on the process requirements for preventing sand production from the formation and proppant flowback, the consolidated sand can be cured in a formation environment of 20-150°C. The artificially formed wellbore wall through curing has excellent flexural properties, which can effectively prevent sand production from the formation and proppant flowback. At the same time, the cured artificial wellbore wall also has good permeability, forming a conductive passage for oil, gas, and water.

The consolidated sand produced by our company is divided into two sub-products: high-temperature curing and low-temperature curing, both of which can achieve excellent sand prevention effects. High-temperature curing is suitable for formation temperatures above 50°C, where the consolidated sand can undergo self-reaction curing under high-temperature conditions, with a curing time not exceeding 72 hours, and the strength of the cured artificial wellbore wall can reach more than 8MPa. Low-temperature curing is suitable for formation temperatures between 20-50°C, where the consolidated sand undergoes low-temperature induced curing under the action of a matching enhancer, with a curing time not exceeding 72 hours, and the strength of the cured artificial wellbore wall can reach more than 10MPa.

No Data Available

No Data Available

share

share

service

service

top

top

Tips

商家中心

商家中心

全部展商分类

全部展商分类

勘探与生产

勘探与生产

工程技术服务

工程技术服务

石油工程建设

石油工程建设

石油装备制造

石油装备制造

天然气与管道

天然气与管道

油田数字化

油田数字化

低碳新能源

低碳新能源

石油化工产品

石油化工产品

物流运输

物流运输

设备五金

设备五金

wechat sharing

wechat sharing

link sharing

link sharing

链接全球

链接全球  精准匹配

精准匹配  在线互动

在线互动  品牌提升

品牌提升  多方共赢

多方共赢  扫码关注公众号

扫码关注公众号  扫码进入移动端

扫码进入移动端