正在建设中,敬请期待

نصائح دافئة

Tips

Tips

Please improve your information and become a senior member

نصائح دافئة

Tips

Trusted stores

Trusted stores

Direct sales

Direct sales

Instant prices

Instant prices

product

Explosion-proof Pressure Testbay Box

product

Explosion-proof Pressure Testbay Box  You may also like

You may also like

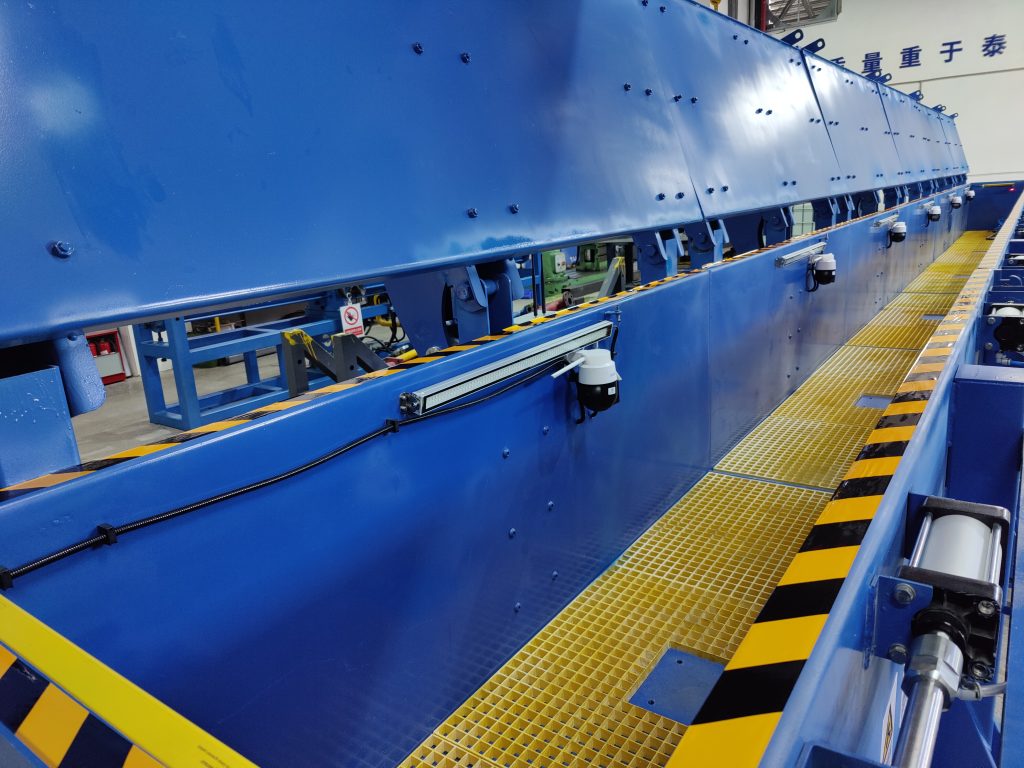

Explosion-proof Pressure Testbay Box

· Explosion-proof Pressure Testbay Box (PTB) is a type of a pressure test equipment for injection of different media such as clean water and glycol.

· It has solid structure, strong impact resistance and wide pressure test range to meet high pressure test application in many industries.

· It’s available to do pressure and temperature test for various pressure vessels, pipelines, valves, downhole tools, cylinder, etc.

· As a kind of customized industrial product, our containerized Pressure Testbay Box have been served in chemical, construction, plumbing, petroleum, coal, smelting, shipbuilding and other industries.

Main Features of the Equipment

1. The control panel of the pressurization unit adopts a modular design, and the operation process is clear.

2. The unit has the function of boosting clean water and glycol.

3. Equipped with automated functions such as digital remote control, real-time data display, monitoring, generating experimental reports, and querying historical data.

4. High strength protective wall made of steel plate, bulletproof fiber, interlayers and other comprehensive materials, so the thickness reaches 70mm. Equipped with high-strength pressure test protection cabin, which can carry out explosion-proof safety prevention and control of high-pressure test.

5. Remote PTZ video monitoring system to observe the on-site conditions and safety.

6. Compressed air unit and pressure test unit are designed separately for ease of use.

7. Having good pressure performance and matching performance.

8. Install the necessary safety valves and pressure control components.

9. Whether it is the length of the box, pressure test valves, or other parameters, they can be customized.

1. Pressure Testbay Box

| Working pressure | 15000 PSI |

| Size | 18m*2m*1.5m (single section: 3m*2m*1.5m) |

| Weight | 12.7 T (single section: 2.1 T) |

| Number of cameras | 6 adjustable cameras with night vision function |

| Lighting | 24V/100W led, quantity: 6 |

| Door opening mode | Hydraulic cylinder telescopic opening |

| Door opening direction | Upward (angle greater than 90°) |

2. HPU

| Max working pressure | 15000 PSI |

| Working voltage | 380V 50HZ |

| Working medium | Water & Glycol |

| Water high pressure outlet | G1/4-60° |

| Water inlet | NPT1/2” |

| Air-driven interface | NPT1/2” |

| Cylinder outlet A and B | φ8mm |

3. Pre-fill Station

| Volume | 1000L |

| Material | HDPE |

| Water outlets | 2*NPT1”(F) |

| Outlet filtration | 40 μm |

| Size | 1500*1300*1400mm |

No Data Available

No Data Available

share

share

service

service

top

top

Tips

商家中心

商家中心

全部展商分类

全部展商分类

勘探与生产

勘探与生产

工程技术服务

工程技术服务

石油工程建设

石油工程建设

石油装备制造

石油装备制造

天然气与管道

天然气与管道

油田数字化

油田数字化

低碳新能源

低碳新能源

石油化工产品

石油化工产品

物流运输

物流运输

设备五金

设备五金

wechat sharing

wechat sharing

link sharing

link sharing

链接全球

链接全球  精准匹配

精准匹配  在线互动

在线互动  品牌提升

品牌提升  多方共赢

多方共赢  扫码关注公众号

扫码关注公众号  扫码进入移动端

扫码进入移动端