正在建设中,敬请期待

نصائح دافئة

Tips

Tips

Please improve your information and become a senior member

نصائح دافئة

Tips

Trusted stores

Trusted stores

Direct sales

Direct sales

Instant prices

Instant prices

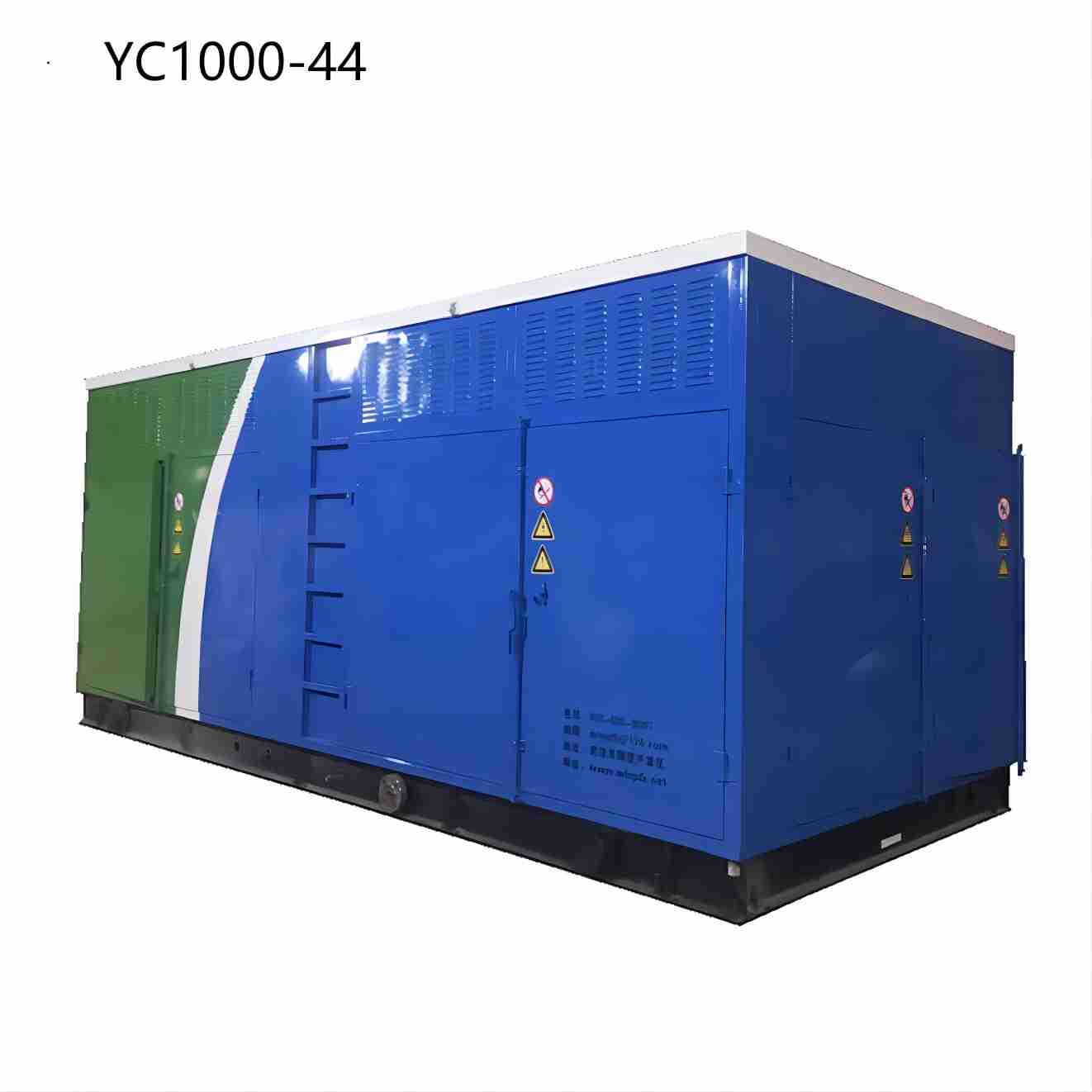

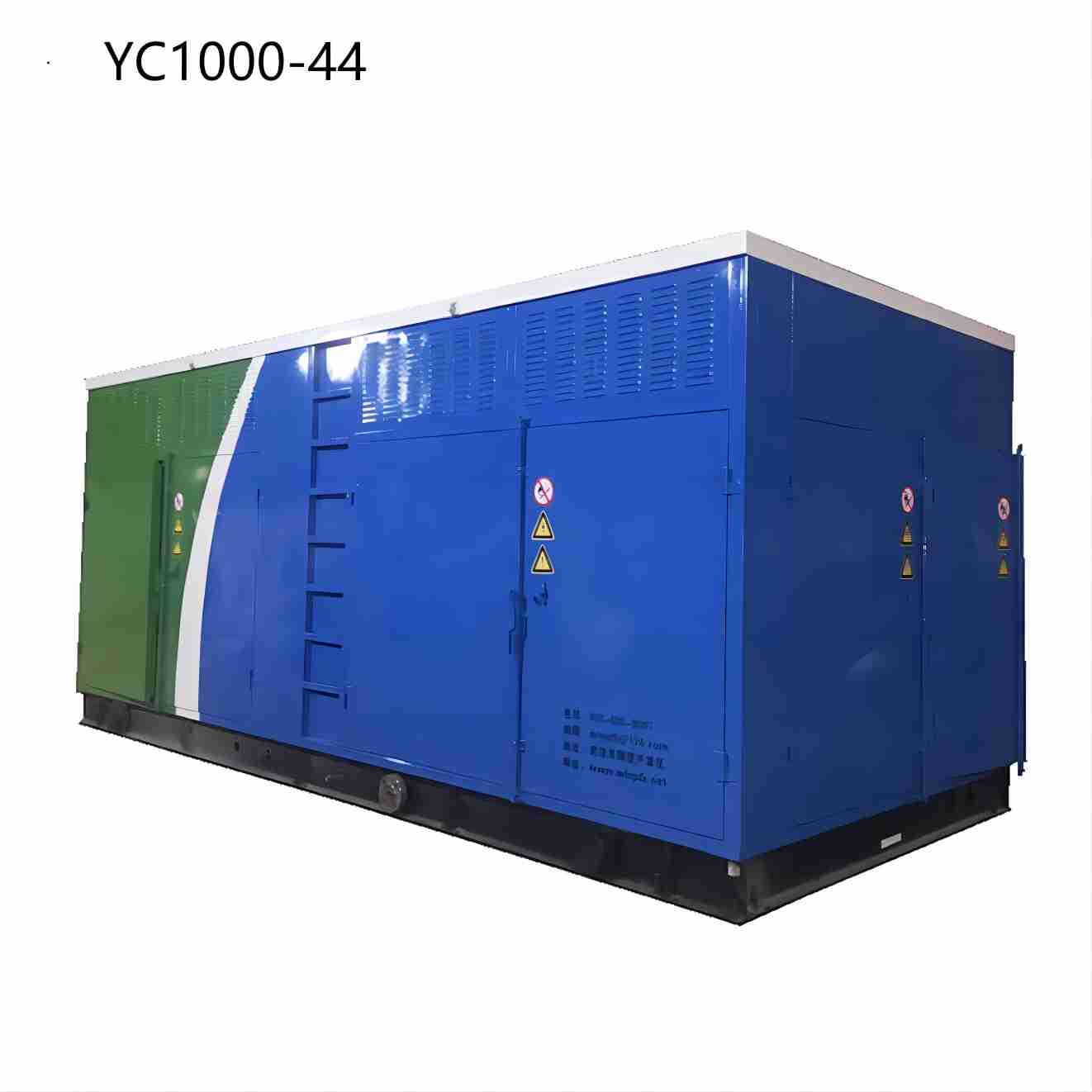

product

Natural gas recovery and treatment device for gas wellhead

product

Natural gas recovery and treatment device for gas wellhead  You may also like

You may also like

1.Product introduction:

This equipment is mainly used for wellhead natural gas recovery of low-efficiency Wells, test production Wells and remote Wells, and produces CNG on site. The recycling device consists of7 systems:

A. Gas intake separation system

B. Supercharging system

C. Drying system

D. Control system

E. Filling metering system

F. Fuel gas supply system

G. Housing system

To better adapt to the field conditions of well gas recovery, the air intake separation system uses a high pressure separator to separate the gas and liquid level, using a liquid level controller to automatically control the liquid level; the pressurization system uses a hydraulic piston compressor, which can meet the intake pressure range of 3-20 MPa. Pressurization to 25 MPa, is more energy-efficient and leak-free than traditional mechanical pressurization, with low failure rate, high reliability and simple maintenance; the drying system adopts the A、B tower molecular sieve mode, which can be dried and regenerated

simultaneously, with a maximum drying capacity of 2000 Nm3h, dew point is -55℃; the control system is controlled by PLC logic control program to control each process such as separation, pressurization, drying, metering, instrument wind and so on, to realize unattended, automatic opening / stopping control; The filling metering system adopts mass Flow-meter, which meets the requirements of the state on metering, measuring range :1~4000 N m3/ h; unit is equipped with a whole rain-proof room, all the process equipment are placed in the room, it has rain-proof, wind-proof, warm and other measures.

The seven systems are arranged on a skid to achieve movable function, short installation period and simple installation.

Parameter

Technical specifications | Type of equipment | ||

YC1000-44 | YC1500-74 | YC1500-135 | |

Structure form | Skid mounted | Skid mounted | Skid mounted |

intake pressure (MPa) | 3-20 | 3-20 | 3-8(3-20) |

discharge pressure (MPa) | 25 | 25 | 25 |

Gas treated ( Nm³/d) | 10000-20000 | 20000-50000 | 20000-50000 |

Amount of treatment (t/d) | 20 | 50 | 50 |

Motor power (kW) | 22+22 | 37+37 | 45+45+45 |

Total power (KW) | 70 | 110 | 170 |

Fuel tank (L) | 600 | 1000 | 1000 |

Scope of measurement (Nm³/h) | 1-4000 | 1-4000 | 1-4000 |

Dimensions (m) | l6.6×w3×h3 | l9×w3×h3 | l10×w3×h3 |

Weight (t) | 18 | 22 | 24 |

Advanteges:

(1) Skidding, high degree of integration, good flexibility, short construction period.

(2) B.High degree of automation, centralized control points, low labor intensity.

(3) Compressor adopts hydraulic piston type, which has the characteristics of wide intake range, energy saving, no leakage, very low failure rate and simple maintenance, so it can better adapt to the characteristics of large variation of well bore pressure range.

(4) No need to be equipped with water jacket furnace and pressure regulating equipment, safety risks are small, no throttling energy waste.

(5) Use high pressure post dehydration, dehydration effect is good, conducive to product sales.

(6) Recovery process equipment has strong adaptability to wellhead pressure and components, and the equipment input cost is small.

(7)The recovery process equipment has strong adaptability to wellhead pressure and components, and the equipment input cost is small

PICTURE

Part1 Our Advantages

1..Professional R&D Team

The company now has more than 30 scientific research and technical personnel, 5 senior engineers. There are 10 staff with intermediate titles and 3 part-time professors and consultants. It is now the Qidakon Technology Center of Huazhong University of Science and Technology, the Qidakon Industry-science base of Huazhong University of Science and Technology, and the Qidakon Collaborative innovation research and Development base of Hubei University of Technology, and was assessed as the district-level technology research and development center of Wuhan Hanyang District by Wuhan Science and Technology Bureau in 2011. In 2012, it was recognized as a national high-tech enterprise. The "New natural gas hydraulic compressor" project independently developed by the company won the National Technology Innovation Fund in 2010, and in the same year, led the preparation and drafting of JB/T11422-2013 "Hydraulic natural gas compressor for automobile filling station" industry standard. In 2015, it was awarded the "Natural gas Booster equipment overall Solution Technology Center" by China Petroleum and Petrochemical Engineering Research Society.

2.Advanced production workshop and strict production process

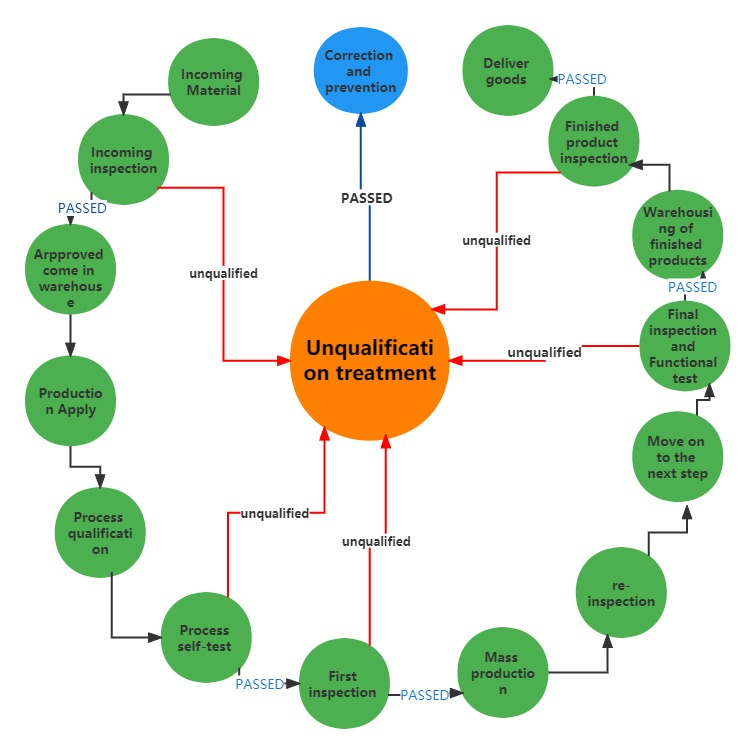

3.Strict quality control process and testing

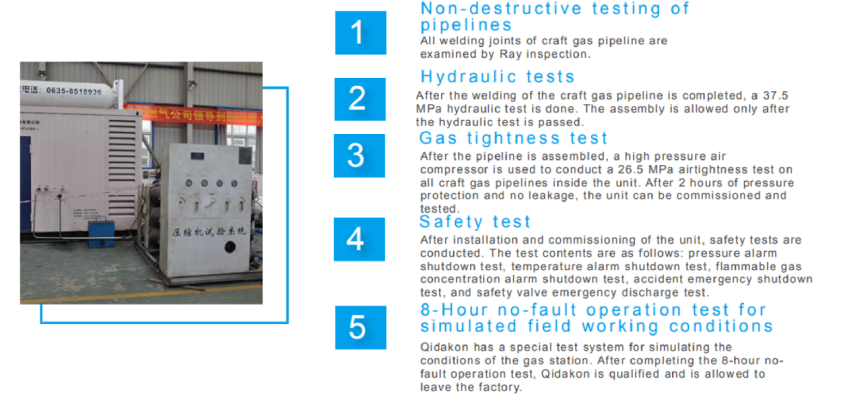

4.Testing of products before delivery

Part2. Certification and Honor

2. After sales service

Pre- Sale Services

Provide installation and commissioning training for customer operators according to customer requirements. At the same time,

organize and register product information and set up customer files.

Services on sale

The professional technical service engineer guides the installation and commissioning on the side or on the line. And warning of the possible failure of the equipment.

After-Sales Service

Timely and rapid response ,24-hour on-line service, provide lifelong maintenance.

Part3 . Partner & Case

CNG REFUELING STATION

No Data Available

No Data Available

share

share

service

service

top

top

Tips

商家中心

商家中心

全部展商分类

全部展商分类

勘探与生产

勘探与生产

工程技术服务

工程技术服务

石油工程建设

石油工程建设

石油装备制造

石油装备制造

天然气与管道

天然气与管道

油田数字化

油田数字化

低碳新能源

低碳新能源

石油化工产品

石油化工产品

物流运输

物流运输

设备五金

设备五金

wechat sharing

wechat sharing

link sharing

link sharing

链接全球

链接全球  精准匹配

精准匹配  在线互动

在线互动  品牌提升

品牌提升  多方共赢

多方共赢  扫码关注公众号

扫码关注公众号  扫码进入移动端

扫码进入移动端